Have you ever wondered how those soft and comfortable diapers that keep your baby dry are made? The process of manufacturing diapers is quite complex and involves several key materials, one of which is wood pulp. In this article, we will explore the fascinating journey from raw materials to the finished product that has revolutionized baby care.

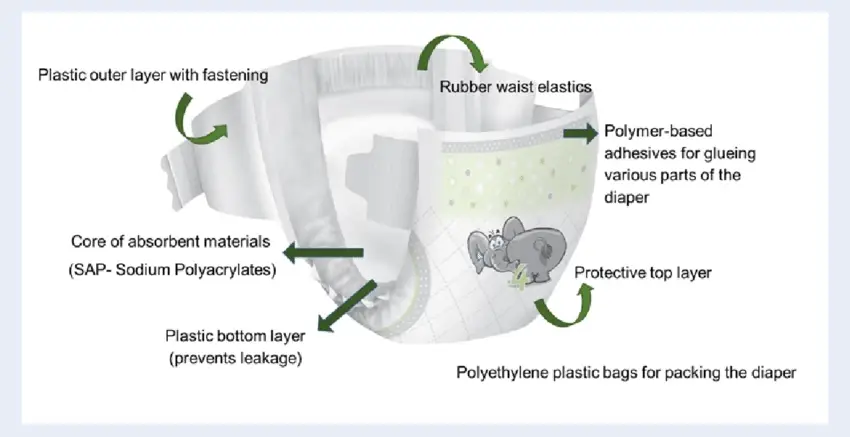

The construction of a baby diaper involves multiple layers, each playing a crucial role in ensuring your baby’s comfort and dryness. The diaper is generally made up of an outer layer, a distribution layer, an absorbent core, and a soft top layer that comes in contact with your baby’s skin.

- Outer Layer: The outer layer, often made of a waterproof material like polyethylene film, prevents liquids from leaking out. This layer may also be treated with lotions or printed with child-friendly designs.

- Distribution Layer: Just beneath the outer layer, the distribution layer’s purpose is to evenly spread the liquid to the absorbent core. This layer is usually made of non-woven material.

- Absorbent Core: Here is where the magic happens. The absorbent core is where wood pulp comes into play. This pulp is often mixed with superabsorbent polymers (SAP) which can absorb and hold a large volume of liquid relative to their size.

- Top Layer: This is the layer that directly contacts the baby’s skin. It’s designed to quickly let liquids pass through into the absorbent core and keep the baby’s skin as dry as possible. It’s typically made of a soft, non-woven material.

Now, let’s focus on the absorbent core and the role of wood pulp. This pulp, also referred to as fluff, is one of the key elements in the diaper manufacturing process. The fluff comes from trees, specifically softwood species like pine and spruce. This wood is processed into small, fluffy particles that can hold many times their weight in liquid.

The wood pulp or fluff is treated and compressed into a pad, which becomes the absorbent core of the diaper. The absorbent core also includes small amounts of SAP, tiny crystals that can absorb up to 30 times their weight in liquid. Together, the wood pulp and SAP ensure that the liquid is effectively absorbed and kept away from your baby’s skin.

The use of wood pulp in diapers is an environmentally-friendly choice, as it’s a renewable resource, and the pulp production process is designed to make the most efficient use of the wood. It’s also biodegradable, which is an added advantage in our quest for sustainable living.

To conclude, the manufacture of diapers is a multi-step process that uses a variety of materials, including wood pulp, to ensure the ultimate comfort and dryness for your baby. The use of wood pulp not only adds to the absorbency of the diapers but also emphasizes the importance of using sustainable and biodegradable materials in our everyday products.